Prioritising Business Processes: How To Select Processes For Improvement

/One of the most important aspects of defining a practical BPM strategy is identifying how processes will be selected. Your approach to selecting business processes for improvement should be carefully planned, otherwise you stand the risk of launching random process improvement projects that do not deliver much value to the business. BPM professionals should understand the different approaches to selecting processes for improvement to prevent adopting a "finger in the air" approach.

The approaches described in this post are not exhaustive but offer a starting point for businesses intending to delve into BPM. As a BPM professional, understanding these approaches is useful for developing a prioritised list of process improvement ideas that will consistently deliver value to the business.

No matter which approach you adopt, process selection should be guided by this basic principle: Only about 20% of organisational processes have the potential to deliver unique competitive advantage (Pareto’s Principle). If you can identify these processes, half the battle is won. The remaining 80% would typically not require heavy improvement work and may be supported by standard software packages.

Approach A

Processes in an organization can be grouped into core, enabling and guiding processes. Core processes have a direct impact on the business or customer and represent the raison d’être of the business e.g. Logistics, Sales, Customer Service, etc. Guiding processes are for planning and directing the business e.g. Planning & Governance processes. Enabling processes on the other hand, provide reusable capabilities and physical assets that can be used for running the business, e.g. HR & IT.

To reduce risk, you may want to start with a process that does not have a direct impact on the customer and then refine your improvement methodology before moving on to core processes which have a high impact on the maturity and performance of the business.

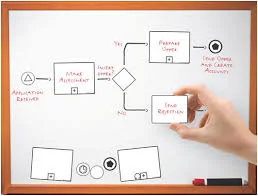

At the core of this approach lies Michael Porter’s Value Chain which recommends adopting a process view of organisations and categorising processes into support and primary processes. Process improvement efforts should focus on activities within the value chain. Process flows may be used to map value-creating activities and illustrate linkages between one activity and another.

Approach B

Mathias Kirchmer and Peter Franz in their book, Value-Driven Business Process Management: The Value-Switch for Lasting Competitive Advantage, emphasise the need to link strategy, process and execution in order to derive value from BPM projects. Their recommendation is as follows:

- Identify your corporate strategy. This is necessary in order to shortlist which processes to target for improvement. As the goals of a company changes, improvement efforts should be adjusted accordingly.

- Create a hierarchy of processes and subprocesses - This is called a logical operating model or a process architecture and its main objective is to illustrate the interdependence of processes and guide the business in identifying which areas would most benefit from improvement.

- Identify the processes that are most critical to delivering value drivers.

- Examine the business. Knowing what you know about the strategic direction of the organization, assess each process with the following questions: What are the benefits of improving the process now? Would improving this process deliver the benefits you are looking for? Assess the processes in the organization for their capacity to deliver both qualitative and quantitative improvements and then examine their impact on the value drivers (e.g to improve customer service). After arriving at the eligible processes, categorise each one based on its level of maturity and target the least mature for improvements.

- Create a road map for improvement. This roadmap connects tasks or activities to value drivers. It represents a schedule of deliverables and the responsible parties.

Approach C

This approach to selecting processes for improvement is reactive and may manifest when:

- Management recommends specific processes for improvement owing to pressing business problems.

- Customers complain about key processes

- Employees submit process improvement ideas

- It becomes glaring that a process has to be improved, especially where there’s a lot of waste involved in its operation.

To solve these problems, projects may be launched and analysts required to conduct process audits to discover how key processes are performing and recommend improvements.

In auditing a process based on reports, the analyst will need to understand: 1) What the pain points are, 2) The steps that cause costs to go up, 3) The steps that affect the quality of products/services, 4) The steps that are time-consuming and 5) The steps that are an impediment to the flow of the process, and so on.

While this approach can be effective in the short term for solving pressing problems, businesses stand to benefit from defining an overarching strategy for managing business processes proactively in the long term.

Approach D

See Implementing BPMS: Selecting the First Process for a case study on how our team selected the first process for automation using pre-defined criteria. The approach we adopted has elements of some of the approaches already described here.

Depending on the peculiarities of an organization such as the level of maturity of its processes, the goal of the process improvement effort and the expertise available, one or more of these approaches may be adopted. Organizations may also switch from one approach to the another throughout the course of managing their business processes.

Picture Attribution: “Priority Tick Shows Correct Mark And Preference” by Stuart Miles/Freedigitalphotos.net

Data and analytics can provide invaluable insights into how your business is performing. Experts like Mark Stiffler say that leveraging data and analytics can uncover new growth opportunities, strengthen existing processes, and increase your overall efficiency. In this blog post, we'll discuss eleven tips you can use to leverage data and analytics to improve your business processes.