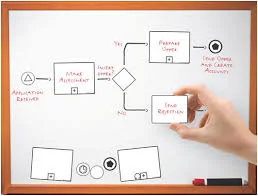

20 Principles Of Business Process Improvement

/Companies undertake process improvement efforts for numerous reasons. If a company is vying to attract investors for example, it must have its ducks in a row. Process information flying around in memos and emails can easily lead to chaos and a general lack of understanding of how things are supposed to work. To work effectively, employees should have a complete view of the effects of their actions and inactions on process outcomes.

Where processes are poorly documented, extra effort is needed to get work done, posing significant risks to the business. To lead a successful Business Process Improvement effort, there are certain principles of success that should be applied.

Abiding by these principles will improve the probability of achieving success on your projects:

- Confirm the strategic direction of the business before you start any process improvement effort and ensure that management support is made both clear and public. Communication from management for example, can help emphasize the importance of the improvement effort to all.

- Ensure that the benefits of the process improvement effort are clearly visible and achievable in the short term. Don’t try to boil an ocean. Even though there are process improvement efforts that deliver benefits in the long term, it’s much better to gain the trust of stakeholders early through quick and visible wins. This will prove to stakeholders, especially management, that you are more than capable of delivering. Remember these words for any process improvement effort: Quick, Visible and Value-Adding. Focus improvement efforts on areas of the business that provide significant impact on performance, cost, quality and service.

- Prepare a business case for the improvement effort. List out all the stages of the project, the resources you will require at each stage, the cost and the estimated duration. Ensure your figures are realistic and that you have considered other alternatives before presenting the business case for approval. See 20 Tips for a Winning Business Case.

- Ensure you get management support and approval before implementation. Imagine a designer who spends a significant amount of time making a dress without getting the customer’s approval of the design first. This could easily result in outright rejection or rework. Develop a plan for the improvement effort and seek management’s approval before implementing any changes. This plan should state exactly how improvement will be achieved to get the approval you need. The approval can serve as leverage for garnering stakeholder support and cooperation on your project. No one wants to be part of a project that management has not “blessed”. Depending on the organizational culture and policy of the organization concerned, it may be necessary to seek another approval before the changes go live.

- Be clear on the benefits the process improvement effort will deliver. Will it save time? Will it improve staff discipline? Will it save costs? Will it help the business achieve its goals? Will it achieve a combination of these? Emphasize how process improvement can help to standardise organisational processes and take the business to the next level. ISO 9001 is one standard you can work towards achieving. The importance of the project you are embarking on should trickle through the organization. Don’t just embark on projects for the sake of it; improvement efforts should be targeted at delivering business value. Presentations, workshops and meetings should always start with a reminder of what these benefits are so that everyone is aware of them upfront. In general, improvements should be centred on increasing worker productivity, efficiency, quality and service.

- Leverage Technology. Technology is not a must-have for business process improvement efforts and so should not determine the direction but should instead, support it. To understand how you can leverage any technology, you need to understand the technology, its limitations and the opportunities that can be exploited. Where a particular technology is not available and you believe it is crucial to achieving the objectives of the improvement effort, make a business case for it so that the full benefits of your process improvement effort may be realised. The message here is to understand what technology assets are available and how you can leverage them. Don’t rush to change tools, however. Not all problems can be solved with technology and it is certainly possible to make a bad situation worse. Improvements done in isolation without considering technical limitations can easily backfire and you may end up devoting time and energy to resolving issues instead.

- Be ready to deal with difficult stakeholders. Stakeholders can be difficult for a variety of reasons; process improvement efforts in some cases, lead to redundancies, expose fraud, mistakes and the incompetencies of employees. Don’t take any pushbacks personally and be willing to step in, thick-skinned as ever and ready to do what needs to be done. See How to Deal With A Difficult Stakeholder.

- Stakeholder Analysis is key to process improvement. The last thing you want to do is embark on an improvement effort only to realise that you have not considered the needs of all stakeholders. Leaving out key stakeholder groups can be both embarrassing and risky. Such stakeholders can pull down your project and spoil everything you’ve worked hard for. Carry everyone along and ensure that "no man is left behind". For your improvement effort to be complete and successful, you need to consider the needs of all stakeholders, even if their involvement in the process is minimal.

- The culture of the organization seeking process improvement must be conducive to change. Imagine an organization where stakeholders decide not to show up for meetings and workshops without repercussion. Improvement efforts in such environments can easily be sabotaged especially if management is not on board. If you are a manager, you will need the support of fellow managers to ensure that your project is successful. Cultivating the right culture and attitude in staff is key.

- Solve the right problem. Don’t just take anyone’s word for it. Try to understand and experience where possible, the problems you are trying to solve. While looking for problems to solve, you should also be on the lookout for improvement opportunities. Looking for improvement opportunities prevents constant firefighting which will help you work smarter, rather than harder.

- Practise risk management. You should be able to predict what obstacles and opportunities lie ahead so that you can manage them. The last thing you want is for the success of your project to be threatened and not even see it coming or give yourself a chance to respond. See Risk Analysis Technique.

- Make sure improvement is continuous. Keep monitoring, keep measuring and keep asking for feedback on process performance.

- Celebrate quick wins to keep team morale high.

- Keep the momentum high throughout the project so that stakeholders do not lose their sense of urgency about what needs to be achieved.

- Learn from your colleagues, customers, etc by asking for feedback. Be open to suggestions for improvement. Requirements change over time and one of the best ways to keep track of them is by interacting regularly with stakeholders to keep them updated on overall progress and seek their feedback. Process improvement efforts involve brainstorming with cross-functional leaders and business teams.

- In the course of improvement, consider whether some processes should be improved, redesigned or eliminated. Focus on reducing waste like redundant work, excessive approvals, inventory overdrafts and excessive labour.

- Adopt an agile approach to requirements elicitation. Don’t expect to elicit all requirements at one go. One way to go about this is to focus on what’s essential and then develop your requirements further as more information becomes available.

- When improving processes, it’s important to dissect and truly understand the root cause of problems thereby preventing the business from making the same mistakes in the future. Techniques like Root Cause Analysis, 5 Whys and Value Stream Mapping can help to accomplish this.

- Create a process “Center of Excellence” to facilitate process improvement by promoting training programs, the use of standardised methodologies, recruitment of qualified personnel, implementing process technology and organising process improvement efforts.

- Measure & Evaluate. To start with, focus on improving only measurable processes. Examples of metrics to capture include inventory levels, costs, sales, lead times, etc. Conducting reviews after project implementation is necessary to verify that the objectives of the process improvement effort have been met and to identify any extra measures that can be taken for improvement. Don’t measure the performance of processes too early, however. This is particularly important if you don’t know what to measure and cannot link your measurements to any strategic business value. In other words, don’t measure just for the sake of it. Start with a qualitative assessment of processes before delving into quantitative metrics, especially with organizations just delving into Business Process Management.

Business Process Improvement is as much about improving the efficiency of business operations and creating projects that lead to increased efficiency as much as it is about instilling an improvement mindset in employees. Process improvement does not end when the project is complete. Processes need to be constantly monitored and measured long after the initial improvement to ensure that they continue delivering business benefits. These key principles should be applied to improve the chances of success.

Picture Attribution: “Improvement Sign Indicates Message Arrow And Advance” by Stuart Miles/Freedigitalphotos.net

Data and analytics can provide invaluable insights into how your business is performing. Experts like Mark Stiffler say that leveraging data and analytics can uncover new growth opportunities, strengthen existing processes, and increase your overall efficiency. In this blog post, we'll discuss eleven tips you can use to leverage data and analytics to improve your business processes.